Compare Oil Skimmers

Over 2000 Oil skimmers – rope and belt types – have been delivered and used worldwide to solve various magnitudes of oil pollution problems. View our graphic to find out more information regarding the various types of oil skimmers including rope, tube and belt to see which type bests suits your application. The rope mop and belt type oil skimmers have power trains available to adapt to most operating conditions including electric, diesel, pneumatic and more. Recovery rates range from one gallon per hour to 8000 gallons per hour. Ambar can design oil skimmers (rope mop or belt type) to meet your needs and solve your waste problem.

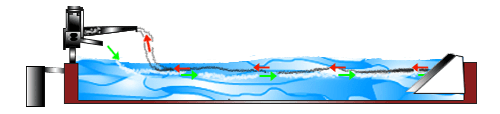

Rope Mop Skimmer

- Mop goes to the oil and doesn’t rely on the oil collecting in one location of the skimming surface

- Mop serves as floating oil boom to contain free oil

- Mop system can be installed to cover the entire surface of the skimming area.

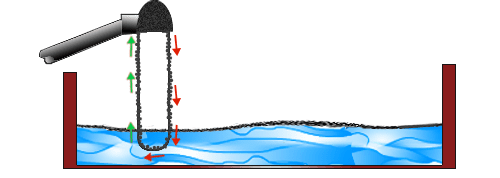

Tube Skimmer

- As with tubes, belts have less surface area per unit length for hydrocarbons to adhere to

- Must locate skimmer in area MOST LIKELY to have majority of oil, leaving many areas unskimmed and laden with oil

- Belt skimmers rely on wipers or squeegees to remove hydrocarbons from the belt which become ineffective when debris comes lodged between the wiper and the belt